2013-12-23

Race Technology DL1 + Dash4Pro

Early Christmas this year when I got myself a Race Technology DL1 Club logger and Dash4Pro dash to go with it.

I've been using a Racelogic Performance box for many years but always longing for a system like this. One big reason for finally upgrading is to be able to see engine performance counters while driving. It can also show alerts when one or a combination of signals are out of range.

It can also show predictive lap time on the fly, and one side of the shift lights can be programmed to show time slip rate so you immediately can tell if a line is faster or not. It also syncs all logged data with my old GoPro camera and can play back the video inside the analysis software.

The display can be set up to display four screens with any of the parameters available. That means all CAN bus data from the ECU as well.

I intend to add a few sensors in the future, such as steering wheel angle and brake line pressure. If feeling extreme I could add wheel speed sensors and suspension movements. The throttle angle I can already get from the ECU.

Instead of using the supplied bracket I drilled two small holes in the steering wheel to mount the display. I wired the power from the windscreen wiper switch so I can turn the system on and off easily.

I'm really looking forward to try the system out this spring!

Labels:

Data acquisition,

ECU

2013-11-02

Fuel filter

MANN WK612/2 or MAHLE KL158. Available in your local car parts store.

Must be one of the parts on this car that is hardest to remove, and even harder to get back due to the tight location.

Take care not to get fuel in your eyes when releasing the pressure. (Don't ask..)

Labels:

fuel,

maintenance

2013-10-29

Uprated fuel pump

In my search for a more robust fuel system the time has come to the fuel pump.

According to Cosworth a 280hk Duratec engine need 1.4L/min regulated to 4.3 bar. That equals 84 L/Hr.

Inside the white container there was a Walbro ERJ 197 fuel pump. The spec sheet says @3 Bar: 108 L/Hr, @5 Bar: 54 L/Hr and is obviously very marginal.

I bought a Walbro 255 LPH from eBay. At 12V and 4.3 bar it can deliver about 180 L/Hr. That is plenty of fuel. In fact, I could run two engines with that pump. If I in the future would decide to run my engine on E85 I could do that too without problems. At least not with the pump.

On the existing pump mount, the big plastic container works as a small swirl pot. The fuel from the return hose goes back into the container and fills it up as a buffer. On the bottom is a one way valve. Instead of sucking air while cornering the pump still can get fuel from the buffer. Since I've always had problems with fuel surge in long corners it apparently doesn't work that well.

On the existing pump mount, the big plastic container works as a small swirl pot. The fuel from the return hose goes back into the container and fills it up as a buffer. On the bottom is a one way valve. Instead of sucking air while cornering the pump still can get fuel from the buffer. Since I've always had problems with fuel surge in long corners it apparently doesn't work that well.

First I tried to make the new pump fit inside the existing plastic container, but as the pump ends are different I couldn't make it fit very well. It worked, but when in a low fuel scenario it would pump air and the pressure would be lost. I verified it by pumping water in a bucket.

Then I modified the existing holder. I straightened one of the tubes. Used an old saw blade and stainless hose clips to hold it together. The old fuel level sensor was wired in place using steel wire. The saw blade acts as a spring and hopefully will keep the pump from moving around too much. The car's tank is v-shaped so it won't move much anyway.

Fuel surge might still be a problem. Maybe even more now without the plastic "swirl pot". I intend to try to put some "Easy Pour Fuel Tank Baffle" in the bottom of the tank to avoid the fuel move around too much. A problem will be the balls obstructing the fuel level sensor, so I can't put in too much of it.

Maybe I should have done it properly with a swirl pot instead.

Now I probably need to remap the engine without the old pump's pressure drop.

According to Cosworth a 280hk Duratec engine need 1.4L/min regulated to 4.3 bar. That equals 84 L/Hr.

Inside the white container there was a Walbro ERJ 197 fuel pump. The spec sheet says @3 Bar: 108 L/Hr, @5 Bar: 54 L/Hr and is obviously very marginal.

On the existing pump mount, the big plastic container works as a small swirl pot. The fuel from the return hose goes back into the container and fills it up as a buffer. On the bottom is a one way valve. Instead of sucking air while cornering the pump still can get fuel from the buffer. Since I've always had problems with fuel surge in long corners it apparently doesn't work that well.

On the existing pump mount, the big plastic container works as a small swirl pot. The fuel from the return hose goes back into the container and fills it up as a buffer. On the bottom is a one way valve. Instead of sucking air while cornering the pump still can get fuel from the buffer. Since I've always had problems with fuel surge in long corners it apparently doesn't work that well.First I tried to make the new pump fit inside the existing plastic container, but as the pump ends are different I couldn't make it fit very well. It worked, but when in a low fuel scenario it would pump air and the pressure would be lost. I verified it by pumping water in a bucket.

Then I modified the existing holder. I straightened one of the tubes. Used an old saw blade and stainless hose clips to hold it together. The old fuel level sensor was wired in place using steel wire. The saw blade acts as a spring and hopefully will keep the pump from moving around too much. The car's tank is v-shaped so it won't move much anyway.

Fuel surge might still be a problem. Maybe even more now without the plastic "swirl pot". I intend to try to put some "Easy Pour Fuel Tank Baffle" in the bottom of the tank to avoid the fuel move around too much. A problem will be the balls obstructing the fuel level sensor, so I can't put in too much of it.

Maybe I should have done it properly with a swirl pot instead.

Now I probably need to remap the engine without the old pump's pressure drop.

Labels:

fuel

2013-10-06

Tierp Arena

My car is both wonderful and terrifying at the same time! Especially in the morning on a wet track with cold slicks... Ehh... The concrete barriers added another dimension to it. During the day the track dried up and I could start pushing, but I had most fun trying to overtake the red Westfield. I was faster but still it is very hard to overtake someone.

The alternator broke again. Since last time I let a local mechanic fix it 'as new' to a reasonable price but it didn't last long. I'm probably over revving it. In the winter I must change the pulleys so it rotates a bit slower.

My shoulders will be sore tomorrow!

Labels:

alternator,

driving,

trackday

2013-09-13

Finally some driving!!

A "test drive a Radical SR3" event at Mantorp. I was also invited but drove my own car.

The engine runs great! The car handles great! Even the weather was great! My driving - not so great, but who cares? Well not that bad, today's best was 1:22.3. Compared with my all time best 1:21.8 it is all right considering I had no "rabbit" in front of me and I was feeling a bit rusty. The Radicals didn't stand a chance with those inexperienced drivers.

But of course...

Today the alternator broke completely.

The same symptoms - no power on the long straight. But this time I knew, and backed off the throttle immediately. Also the no-charge light on the dash was lit this time.

I also experienced fuel surge in the long right hander "Parisern" when the fuel level was below half. I always had that problem, even with the stock CSR200 engine. Today it annoyed me more than ever before.

I need a more robust fuel system! I can't risk loosing my engine because the alternator fails, or if a connector jumps loose.

Anyway I got five or so laps on film. Here are a couple of them. I'm not very satisfied with my driving here, as soon as I try to push hard I get sloppy and miss the apexes.

The engine runs great! The car handles great! Even the weather was great! My driving - not so great, but who cares? Well not that bad, today's best was 1:22.3. Compared with my all time best 1:21.8 it is all right considering I had no "rabbit" in front of me and I was feeling a bit rusty. The Radicals didn't stand a chance with those inexperienced drivers.

But of course...

Fuel surge and alternator problems!!

This spring when my engine broke, it was because of the small wire from the alternator went loose and it stopped charging the battery. The fuel pump couldn't keep up with the lower voltage and the engine run lean. Things got hot inside the cylinders and the engine got damaged.Today the alternator broke completely.

The same symptoms - no power on the long straight. But this time I knew, and backed off the throttle immediately. Also the no-charge light on the dash was lit this time.

I also experienced fuel surge in the long right hander "Parisern" when the fuel level was below half. I always had that problem, even with the stock CSR200 engine. Today it annoyed me more than ever before.

I need a more robust fuel system! I can't risk loosing my engine because the alternator fails, or if a connector jumps loose.

Anyway I got five or so laps on film. Here are a couple of them. I'm not very satisfied with my driving here, as soon as I try to push hard I get sloppy and miss the apexes.

2013-09-10

Brise starter

This is the second time my starter solenoid has broken. It is a mechanical failure where the plastic actuator arm inside the coil has broken off. The starter motor has also been very sluggish lately and not always been able to crank the engine when the engine has been hot!? If it is the solenoid that has been causing that too, I don't know. I do know it's not the battery, because I've replaced that one too. And it is not the wiring either.

I've been forced to ask a random person for help at a parking lot many times. So I just want it fixed and have installed a new Brise starter because "they're the best" according to a reseller.

And the difference is??

I don't know. I just hope it works better than the old one. The casing looks very similar for sure. It appears to turns the engine with much more determination than the old one. I read somewhere the gearing is different and that is probably why it copes better with high compression engines like mine.

2013-09-09

Thermal camera

During the last F1 race they've equiped some of the cars with thermal cameras. How cool is that??

Notice how fast the tires cool on the straights, and how much heat is generated from just a small mistake. Some interesting words about it here. I also wrote something about wide tyres and heat a while ago, here.

Of course you'd want a camera like that yourself. The problem is that the price tag for an entry level thermal camera is several thousands of dollars.

There is soon a solution for that. Check out this camera that you attach to your smartphone. The estimated retail price is "just" $325!

2013-08-24

Head job

The previous engine damage was not fixed. The car was lacking power, and another compression test still gave low figures on the middle two cylinders. Since the bottom end is fixed for sure, that leaves the valves.

I just had the engine disassembled, why didn't I examine the head more thoroughly? Stupid!

Anyway, head off. With the engine still in the car it took just a couple of hours to get it apart. It is funny how much easier things are when you've done it before. Separating the head from the engine was for me something unthinkable not long ago.

A water test confirmed that the middle two cylinder's valves was leaking. So, time to disassemble the head as well. That is a bit more time consuming but not very hard, and can be done inside at the kitchen table :-)

- Do you have to keep the engine in the kitchen?

- It is just the head, dear.

- Ah, ok then.

Almost all of the valves on the middle two cylinders was damaged, both on the intake and exhaust side. Fortunately all of the valve seats looks as new. The pitting on a couple of the valves looked like it could have been caused by a foreign object. But if that was the case wouldn't it be dents in the seats as well? No, I still believe in the fuel starvation theory.

Seven new valves. Some lapping compound and the valves sealed again.

Here is a really good YouTube video of how to make a basic valve job.

Damn! Now what? I just want my engine back!

After a bit of grumble I decided to do the test again, this time being extra super careful with the cam timing. And the clearance was back. Now I know how sensitive it is. Under no circumstances the exhaust cam should be retarded. In fact, one or two degrees advanced exhaust timing is not wrong to be on the safe side. The same goes for the intake cam, but the other way around. I don't believe it was this sensitive with the old engine block.

First start today and first test drive this tonight. Always hard to tell if all the power was back or not, especially when it is dark outside, but the engine felt good and a new compression test gave the same results on all the cylinders.

Yay!

|

| Damaged intake valve. Caused by excessive heat? |

I just had the engine disassembled, why didn't I examine the head more thoroughly? Stupid!

Anyway, head off. With the engine still in the car it took just a couple of hours to get it apart. It is funny how much easier things are when you've done it before. Separating the head from the engine was for me something unthinkable not long ago.

A water test confirmed that the middle two cylinder's valves was leaking. So, time to disassemble the head as well. That is a bit more time consuming but not very hard, and can be done inside at the kitchen table :-)

- Do you have to keep the engine in the kitchen?

- It is just the head, dear.

- Ah, ok then.

Almost all of the valves on the middle two cylinders was damaged, both on the intake and exhaust side. Fortunately all of the valve seats looks as new. The pitting on a couple of the valves looked like it could have been caused by a foreign object. But if that was the case wouldn't it be dents in the seats as well? No, I still believe in the fuel starvation theory.

Seven new valves. Some lapping compound and the valves sealed again.

Here is a really good YouTube video of how to make a basic valve job.

Piston-to-valve clearance check

Before I put the head back to engine I decided to do a piston-to-valve clearance test using modelling clay. It is a very tediously process where you put some clay in the cylinder, and then mount the head, cams and timing chain back together and then turn the engine two turns and disassemble it again. To my surprise the clearance was about half of the Cosworth recommended 1.00mm!Damn! Now what? I just want my engine back!

After a bit of grumble I decided to do the test again, this time being extra super careful with the cam timing. And the clearance was back. Now I know how sensitive it is. Under no circumstances the exhaust cam should be retarded. In fact, one or two degrees advanced exhaust timing is not wrong to be on the safe side. The same goes for the intake cam, but the other way around. I don't believe it was this sensitive with the old engine block.

Lash

"Lash" is the distance between the underside of the cam lobe and cam follower and is checked using feeler gauges. Because of the new valves I was required order four new cam followers from Burton. DHL is the best. They're the only freight company where my experiences has been positive most of the times.First start today and first test drive this tonight. Always hard to tell if all the power was back or not, especially when it is dark outside, but the engine felt good and a new compression test gave the same results on all the cylinders.

Yay!

Labels:

Engine damage

2013-08-10

Roll cage padding article

| Not SFI approved. |

Link to article

Choose a SFI 45.1 approved padding.

Labels:

cage,

links,

protection

2013-07-23

Engine rebuilt

I spent the first part of my summer vacation to rebuild the damaged engine.

New block and new pistons, and a new built loom.

Started without troubles, but I forgot to turn on the video recorder!

A couple of test runs without issues. Ahh I've missed this!

My family is a bit tired on me working on the engine but now I can take a real vacation and enjoy the short summer.

Meanwhile - read Croc's article Getting decent video audio on your Seven.

Labels:

Engine damage

2013-07-11

New engine block

|

|

| New Cosworth pistons. I reuse the rods as they're not damaged. |

I couldn't find a replacement Duratec 2.3 block in Europe so I had to order one from California.

GPWerks had both new and used blocks. It took a while to get it but eventually a brand new block arrived.

Beware of TNT Express! They're totally incompetent and should really change their slogan. I'm surprised they manage to deliver any packages at all!

Now I could start to rebuild the engine, I thought, until I dropped a spanner and damaged one of the main bearings.

I ordered new bearings from xpower-engines at eBay and they were very helpful and posted the bearings right away. I can start with other parts in the meantime.

Labels:

Engine damage

2013-07-04

New engine loom

Last time I rebuilt the engine I bought a generic Duratec loom from SBDev. Very nice quality and well made loom. But as it only had wiring for controlling the engine and not for fans, starter relays, dash gauges etc I made my own loom for that.

It worked fine but it looked like crap. Now when I'm waiting for engine parts and have nothing better to do I decided to do it again but with some more effort this time. I also wanted wiring for a few more sensors to the ecu and a future data logger.

The new loom have these connectors:

I started by doing a template with some wire, tape and zip ties.

Then the actual wires.

Lots of heat shrink tubing, and some of the connectors

It worked fine but it looked like crap. Now when I'm waiting for engine parts and have nothing better to do I decided to do it again but with some more effort this time. I also wanted wiring for a few more sensors to the ecu and a future data logger.

The new loom have these connectors:

- Starter solenoid

- Starter relay

- Water temperature (dash)

- Alternator warning light

- Fan 1

- Fan 2

- Fan relay

- Oil pressure sensor

- Oil temp sensor

- Fuel pressure sensor (future)

- Data logger (future)

- Chassis connector

- MBE 1 (existing connector on engine loom)

- MBE 2 (new)

- +12

- GND

I started by doing a template with some wire, tape and zip ties.

Then the actual wires.

Lots of heat shrink tubing, and some of the connectors

And here it is!

Heat shrink tubing, the best since sliced bread

I haven't tested it in the car yet, but what could possibly gone wrong? ;-)

Labels:

electrics

2013-06-26

Cranks and rpm limit

A Duratec 2.3 engine can safely be revved up to 7200 rpm with the standard valve springs. With uprated springs it the limiting factor is the crank and according to Cosworth it can be revved up to 7700 rpm with the standard crank. Above that, a very expensive steel crank is needed. (source)

Among other places, a thread on Pistonheads several people writes that the standard crank may be up for more than 7700 rpm. On my engine the power curve was still climbing when I hit the rev limiter and I would probably gain some top end power if I could raise the RPM limit to say 8000.

What kills a crank is not power or torque, it is RPM. The force on the crank is exponential to the rpm. (source missing) That's why forced induction engines can have very much power and still use the standard crank, as long the rpm limit is kept down. Apparently the forces are specially high during downshifting.

I wrote an email to a Ford Focus engine builder and asked about their view on the subject.

I did a simulation in Optimum Lap and a 8000 rev limit would do about 0.5 seconds on Mantorp. Not much and I'm doubtful it is worth the extra risk and engine wear, but as my engine is in pieces I went to a engine workshop anyway to have my crank, pulley, flywheel and clutch balanced. It doesn't cost much and it would decrease the loads on the bearings even if I increase the rev limit or not. I also hope it would reduce some vibrations at high rpm making it easier to stay focused on the race track.

The mechanic explained they put the crank in their machine and start rotating the crank and measuring the imbalance. After some adjustments by removing metal the balance "was zero" and he put on the flywheel and balanced again. Then the clutch and finally the front pulley. That way individual components can be replaced without the need to rebalance the crank. On V engines the weight of the crank counterweights depend on the weight of the rod and piston. That is not true for inline-4 engines as there is always the same weight going the opposite direction. (as long as the piston/rod assemblies are of equal weights, which they normally are if bought as a set)

More very informative reading about cranks here.

|

| Balanced crank and front pulley |

What kills a crank is not power or torque, it is RPM. The force on the crank is exponential to the rpm. (source missing) That's why forced induction engines can have very much power and still use the standard crank, as long the rpm limit is kept down. Apparently the forces are specially high during downshifting.

I wrote an email to a Ford Focus engine builder and asked about their view on the subject.

"For us we have a race car and we redlined it at 8500 with no problems ever. But the engine was balanced and we even balanced it with the flywheel and clutch to make sure it was perfect! It can be done but just take all precautions needed..."

I did a simulation in Optimum Lap and a 8000 rev limit would do about 0.5 seconds on Mantorp. Not much and I'm doubtful it is worth the extra risk and engine wear, but as my engine is in pieces I went to a engine workshop anyway to have my crank, pulley, flywheel and clutch balanced. It doesn't cost much and it would decrease the loads on the bearings even if I increase the rev limit or not. I also hope it would reduce some vibrations at high rpm making it easier to stay focused on the race track.

|

| Balanced clutch and flywheel |

More very informative reading about cranks here.

Labels:

clutch,

Engine,

Engine rebuild

2013-05-26

Engine damage

|

Bad start this year.

The fuel surge on last trackday caused more damage than I initially thought.

|

| Damaged spark plugs. These are from cylinder #2, #3 and #4 |

I had to take the engine apart.

The pistons are damaged, and so is the block. I put the block into the trunk of the daily driver and asked around among professionals and the verdict is that three pistons are gone, the block can be saved but it would be easier and cheaper to simply buy a new one. Fortunately the head and the rods are not damaged at all.

|

| Damaged block and #3 piston |

|

| Damaged piston |

I found a good document about piston damage.

Except that, all bearings and everything else looks as new.

The people I've asked about the engine agrees with my theory of what happened - the alternator stopped charging, and when the battery discharged during the day the fuel pump could not keep up on the long Mantorp straight and the engine run lean.

Labels:

Engine,

Engine damage,

failure

2013-05-07

Mantorp first time 2013

This years first trackday was a warm day with blue skies on Mantorp and a huge mix of different types of cars.

Things didn't go that well. It started with me being a bit late.

Then there was a Porsche that spilled oil on a long section of the track. (Those German cars....)

Then someone else went off and one corner was covered with gravel and the track was closed again.

When I finally got the tires warm there was too much traffic and no clear laps.

Things didn't go that well. It started with me being a bit late.

Then there was a Porsche that spilled oil on a long section of the track. (Those German cars....)

Then someone else went off and one corner was covered with gravel and the track was closed again.

When I finally got the tires warm there was too much traffic and no clear laps.

Engine problems

Lost top end power and the top speed on the straight was a bit too low. It got worse and worse, so I stopped driving and went home instead, worried that there was something very wrong with the engine.When I got home I did some troubleshooting and found out the alternator warning light connector was broken, and that prevented the battery being charged. (Stupid design!) My speculation is that the battery's voltage went down during the day and caused the fuel pump not being able to keep up the pressure when the fuel demand was peaking, making the engine run lean. Running an engine like this lean is not good at all and could cause fatal pre-ignition.

I need some way to prevent this from happening again.

I would like to be able to log the fuel pressure, and have some warning system for a fuel or oil pressure drop.

Here is a video I found describing how voltage affects the fuel pump flow:

http://www.youtube.com/watch?v=RjykWzDr1Kk

Noise check

A couple of months ago I bought a cheap noise meter from Hong Kong, and today I asked someone to measure the drive-by noise of my car.

The guy told me it made 106.4 dbA!

In many race circuits in this country have from this season a drive-by noise limit of 95dbA.

I started measuring the other cars, and no-one, except a stock Corvette, was below that limit.

Then I moved a little, and all readings changed. Then the wind changed, and the readings changed as well. Then I realized I could not get the same reading twice for the same car.

It seems like measuring noise at a race track is not an exact science.

I refuse to think my car makes as much noise as 106db, but I'm not surprised I have to do something about it if I'd like to drive on other circuits. I just don't know what yet.

In many race circuits in this country have from this season a drive-by noise limit of 95dbA.

I started measuring the other cars, and no-one, except a stock Corvette, was below that limit.

Then I moved a little, and all readings changed. Then the wind changed, and the readings changed as well. Then I realized I could not get the same reading twice for the same car.

It seems like measuring noise at a race track is not an exact science.

I refuse to think my car makes as much noise as 106db, but I'm not surprised I have to do something about it if I'd like to drive on other circuits. I just don't know what yet.

What about all the work done this winter?

All good!

The roll cage... stayed in place.

The suspension bushes hold together. The car felt nice and precise.

The exhaust manifold was not leaking!

The silencer mounts did not break.

No oil spew from the catch tank.

Engine did not leak oil from the front cover

Overall the car feels wonderful. Too bad I was worrying about the engine instead of enjoying myself.

I did not have the aeroscreen mounted as I didn't think it would do much difference. At the end of the straight the force against the helmet was overwhelming. I must put the aeroscreen back on.

Labels:

alternator,

battery,

driving,

Engine damage,

failure,

Mantorp,

noise,

trackday

2013-04-13

Cornerweight, for real

Last attempt to weight my car using bathroom scales failed miserably, so I took a trip to Speedlab Racing and got help so set up the corner balance properly using their professional equipment.

Without driver the car weighted 590kg, race ready with a bit more than half tank of fuel.

After some adjustments a perfect 50% cross weight was achieved.

|

| With driver and helmet, without nose-cone and bonnet. |

It was also fun to take a look at their awesome Corvette-based race car! It is really something extra and worth a trip on its own. Take a look at their home page!

Labels:

corner weight

2013-04-07

Does wider tyres equals more grip?

On a thread on Pistonheads someone claimed that wider tyres doesn't mean more grip.

I would say that the author of that comment is both right and wrong. The reasons why is far from obvious. I'm not an expert in any way but I do enjoy reading up on subjects that interest me. Race car rubber is one of them! But please take it for what it is.

Contact patch

Contrary to common belief the contact patch is not bigger with wider tyres, with the same internal pressure. The contact patch is calculated with area=load/pressure. With wider tyres the contact patch is obviously wider than with a narrow tire, but the area is the same.

Amontons 2nd law is tempting to use here, but rubber's friction is not that simple. Rubber generates friction in three different ways: adhesion, deformation, and wear. The generated friction force is not linear and very complicated.

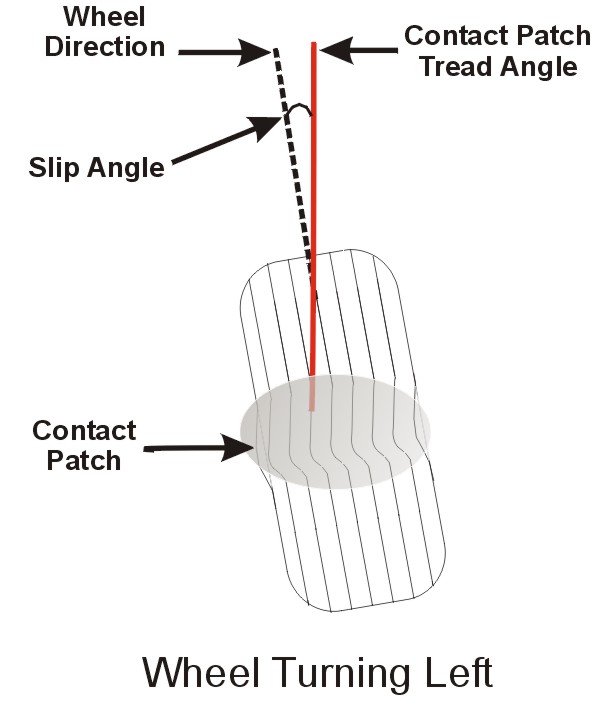

Slip angle

Slip angle is what generates grip, or to be more precise - lateral force. When a race car is cornering, the slip angle is the difference in what direction the tyres are pointing and the direction the car is heading. A race car generates maximum lateral force around 7-11 degrees of slip.

The term "slip angle" is a bit missleading, as with small slip angles there is no slip in the contact patch. In fact, it is the elastic nature of rubber that does the work here.

Lateral deformation in the contact patch

This is where the magic begins. The lateral force is generated by the tyres resistance to deflection. The deflection is not the same along the contact patch, but is built up gradually, non-linear.

So what is your point??

That wider tires do provide higher levels of lateral grip, because the wider contact patch leaves more room for the tyre to resist deflection. And resistance for deflection = force.

And heat?

More grip = more energy = heat. Too much of it means overheating, to little means cold tires. Wider tyres get warmer (not cooler) than narrow tires, because they generate more lateral force! They also cool faster than narrow tyres, because they have a larger surface area. And that is what makes it problematic.

Conclusion

Wider tyres = more grip in the corners. If you don't utilize the higher level of grip, they'll cool too much on the straights and they'll be outside of optimal temperature range.

Source and recommended reading:

The racing & high-performance tire - Paul Haney

When I wrote this post I sent an email to Paul to confirm a few thoughts. He wrote back to me within an hour - respect!

Theoretically, the tyre size does not change grip as Amontons 2nd law states that friction force remains the same. The tyre size is really about matching width to the amount of energy being transferred to the ground, i.e. narrower tyres will run hotter.

Before I get shot down in flames, there are many other factors but the principle that a wider tyre will provide more grip is not necessarily the case unless you have the power to keep them warm.

I would say that the author of that comment is both right and wrong. The reasons why is far from obvious. I'm not an expert in any way but I do enjoy reading up on subjects that interest me. Race car rubber is one of them! But please take it for what it is.

Contact patch

Contrary to common belief the contact patch is not bigger with wider tyres, with the same internal pressure. The contact patch is calculated with area=load/pressure. With wider tyres the contact patch is obviously wider than with a narrow tire, but the area is the same.

Amontons 2nd law is tempting to use here, but rubber's friction is not that simple. Rubber generates friction in three different ways: adhesion, deformation, and wear. The generated friction force is not linear and very complicated.

Slip angle

Slip angle is what generates grip, or to be more precise - lateral force. When a race car is cornering, the slip angle is the difference in what direction the tyres are pointing and the direction the car is heading. A race car generates maximum lateral force around 7-11 degrees of slip.

The term "slip angle" is a bit missleading, as with small slip angles there is no slip in the contact patch. In fact, it is the elastic nature of rubber that does the work here.

Lateral deformation in the contact patch

This is where the magic begins. The lateral force is generated by the tyres resistance to deflection. The deflection is not the same along the contact patch, but is built up gradually, non-linear.

So what is your point??

That wider tires do provide higher levels of lateral grip, because the wider contact patch leaves more room for the tyre to resist deflection. And resistance for deflection = force.

And heat?

More grip = more energy = heat. Too much of it means overheating, to little means cold tires. Wider tyres get warmer (not cooler) than narrow tires, because they generate more lateral force! They also cool faster than narrow tyres, because they have a larger surface area. And that is what makes it problematic.

Conclusion

Wider tyres = more grip in the corners. If you don't utilize the higher level of grip, they'll cool too much on the straights and they'll be outside of optimal temperature range.

Source and recommended reading:

The racing & high-performance tire - Paul Haney

When I wrote this post I sent an email to Paul to confirm a few thoughts. He wrote back to me within an hour - respect!

2013-03-05

Nose cone aero whiskers

I glued them on with melt glue until I was satisfied with the positioning.

Then I drilled three small holes through each whisker, removed the glue and pop riveted them in place.

Labels:

aerodynamics

2013-02-23

Supercharged CSR for sale

There is a supercharged CSR for sale at PistonHeads with some interesting technical solutions.

As one can see the air intake is on the rear part of the bonnet through a remote filter canister and the plenum has its intake on the underside. The intercooler intake is below the radiator in the front.

I suppose the pedal box would make a solution like this much harder on a LHD car.

UPDATE: More pictures

As one can see the air intake is on the rear part of the bonnet through a remote filter canister and the plenum has its intake on the underside. The intercooler intake is below the radiator in the front.

I suppose the pedal box would make a solution like this much harder on a LHD car.

UPDATE: More pictures

Labels:

supercharging

2013-02-20

Exhaust manifold leak

Last summer I bought new exhaust manifold because the old EU4 manifold was warped and had a crack in the collector. The new ones has been leaking as well. I don't know why, if it is a quality issue from the factory or if I have managed to warp them myself.

I've been asking around my local workshops if they could help me, but they all have been shaking their heads saying it would be too troublesome to fix the primaries at their milling machine and that it would be too expensive and not worth it. The last one gave me the suggestion to try to simply use some sand paper on a flat surface and grind them myself.

I've been asking around my local workshops if they could help me, but they all have been shaking their heads saying it would be too troublesome to fix the primaries at their milling machine and that it would be too expensive and not worth it. The last one gave me the suggestion to try to simply use some sand paper on a flat surface and grind them myself.

So I did.

I was sceptical at first but I think this will work!

I made the brackets myself last summer. I think it is the third attempt, the others has cracked after track driving.

Read here to get an idea how it looks like on the car.

I've been asking around my local workshops if they could help me, but they all have been shaking their heads saying it would be too troublesome to fix the primaries at their milling machine and that it would be too expensive and not worth it. The last one gave me the suggestion to try to simply use some sand paper on a flat surface and grind them myself.

I've been asking around my local workshops if they could help me, but they all have been shaking their heads saying it would be too troublesome to fix the primaries at their milling machine and that it would be too expensive and not worth it. The last one gave me the suggestion to try to simply use some sand paper on a flat surface and grind them myself.So I did.

I was sceptical at first but I think this will work!

I also went to a welder - Zanders - and had my silencer mounting brackets reinforced. They used to have a bit of flex and maybe that could be a part of the problem with the warped manifold. I still have a bit of flex. If this doesn't work I'll try to mount the silencer to the forward roll cage mount.

I made the brackets myself last summer. I think it is the third attempt, the others has cracked after track driving.

Read here to get an idea how it looks like on the car.

2013-02-11

DIY Cornerweight

I've been looking for corner weight scales for rent at a reasonable price for some time now without success.

I've been looking for corner weight scales for rent at a reasonable price for some time now without success.At the local Biltema store 130 kg analogue bathroom scales was only €5 each, so I bought a complete corner weight rig consisting of 8 scales for less than what it would cost me to rent racing scales a few hours. Not as accurate of course, but I thought that hopefully they was accurate enough and I can do it any time I want.

Well, they weren't.

When I was standing on a scale, my body weight shifted +/- 10 kg depending on if I was standing on my toes or on my heels.

First I tried with a piece of plywood to even out the weight, but it did not help much. I got the same readings without it and easier to handle.

I repeated the measurements multiple times and the readings was a bit more consistent than I expected, within 10-15 kg. Still not good, but maybe enough for a very rough corner weight adjustment.

I repeated the measurements multiple times and the readings was a bit more consistent than I expected, within 10-15 kg. Still not good, but maybe enough for a very rough corner weight adjustment.Anyway I don't trust them, even for my own body weight.

Labels:

corner weight,

suspension

2013-02-10

Full rollcage

A couple of YouTube clips (here and here) made start thinking about getting a full roll-cage for my car.

When a found one second hand in UK I went for it. DHL shipped it to me and even if the freight was not cheap it was not as much money as one could expect.

|

| Big boys big toys |

The forward frame bosses was easy to find through the side skin using a magnet. I drilled with a small drill and then enlarged the hole with a dremel tool.

I put protective cardboard on the fenders and scuttle sides and test mounted the cage and realized that the cage fouled the FIA battery master switch.

I filled the hole with chemical metal. I think that with some padding and paint will make it look ok, but I leave that for now. I've made a new hole 5 cm to the right of the old one.

A couple of the cage bolt holes was a little bit off, so they had to be enlarged a mm to fit with the chassis.

The hood sticks didn't fit with the cage, so they had to be removed.

The standard half door doesn't fit. Maybe they can be modified and stuck between the cage and car? Lets see about that.

Rear view mirrors direct fit.

FIA Bar + pettystut 11kg

Rollcage 20kg

A bit heavier, but the chassis is probably much stiffer with the cage mounted.

I need some cage padding, some paint for the old battery master switch hole, and half doors that fit. The trunk cover is also a bit loose now without the hood sticks.

All of these changes can be reverted (except for the new hole), but it's not something you do every day. It feels like my car is more of a race car now than a road car. I suppose had to decide what path to take some day, and this is probably it. I also don't know what the yearly MOT will say about the cage.

Labels:

cage,

protection

2013-01-16

Oil catch tank

After my engine rebuild I changed the oil system to an open system and needed a catch tank. Until now I've been using a temporary solution which in every way was not very good.

FIA regulations stipulates that engines larger than 2000cc must have 3l catch tank. I'm not competing, but while I'm at it there are no reasons not to conform to regulations.

For some reason catch tanks with 3l capacity are not very common, and those that would fit under the bonnet are even less so. I ended up having one custom made. The price was about the same as buying an existing design from eBay plus vat.

I sent a sketch to Mulberry Fabrications - Mulfab and not much later I had it in my hand. It is very light, only 763g including filter.

The catch tank is fastened using rivnuts. Some day I'll replace the hoses to something more flexible as they're a bit bulky as it is now.

FIA regulations stipulates that engines larger than 2000cc must have 3l catch tank. I'm not competing, but while I'm at it there are no reasons not to conform to regulations.

For some reason catch tanks with 3l capacity are not very common, and those that would fit under the bonnet are even less so. I ended up having one custom made. The price was about the same as buying an existing design from eBay plus vat.

The catch tank is fastened using rivnuts. Some day I'll replace the hoses to something more flexible as they're a bit bulky as it is now.

Labels:

Engine rebuild,

oil system

2013-01-12

Front damper spherical bearing play

There was a play in the joint between the rocker arm and damper in the front suspension, noticeable when I jack the car up, removed the wheel and lift the suspension at the hub. I decided to change the spherical bearings.

I changed the upper bearings on both sides as I thought that would be enough. Now when the suspension is reassembled I can still feel a small play in one of the lower bearings, sigh...

- First step was to remove the dampers. Remove push rod from lower wishbone. Undo damper bolts starting with the lower bolt.

- The misalignment spacers on one of the dampers was tough to remove, but eventually they got out with some help from a blow torch. Warning! Heating bearings could give off hazardous fumes. These fumes can be harmful to the eyes and to the lungs, if inhaled. Source: SKF.

- Remove retainer circlip with a pointy sharp tool.

- Carefully remove bearing using a socket and a hammer.

- Bilstein part number E4-B46-610. Can be obtained from Caterham Parts or directly from Bilstein. You can also find similar bearings at your local bearing shop in different qualities.

- When I fitted my new bearings I noticed a small play between the new bearing and housing. I used Loctite 648 retaining compound as glue. I don't want any movement there, or the shocks could easily be ruined. I hope the new bearings will outlive the shocks, as they probably is going to be tough to remove in the future. (Heating them might work)

- Reassemble. A good opportunity to replace the bolts and nuts as well.

Note: I have the "race spec suspension" on my car. The procedure and part numbers may be different on the road spec dampers.

I changed the upper bearings on both sides as I thought that would be enough. Now when the suspension is reassembled I can still feel a small play in one of the lower bearings, sigh...

Labels:

maintenance,

suspension

Subscribe to:

Comments (Atom)